Surface Finishing

Basic material surfaces

2B (IIIc)

- cold-rolled metal with 2B (IIIc) surface in accordance with EN 10088-2

- smooth and slightly reflective surface, uniformly gray color

- surface irregularities that appear during the production process are tolerated

- metal roughness (before tank production): 0.1 μm < Ra < 0.5 μm

- product roughness is not inspected

2R (IIId, BA)

- cold-rolled metal with 2R (IIId) surface in accordance with EN10088-2, bright annealing

- very smooth, bright and highly reflective surface

- surface irregularities that appear during the production process are tolerated

- metal roughness (before tank production): 0.03μm < Ra < 0.1 μm

- product roughness is not inspected

1D (IIa)

- hot-rolled metal with 1D (IIa) surface in accordance with EN10088-2

- slightly rough, minimally reflective surface

- most frequently used with thicker sheet metal

- surface irregularities that appear during the production process are tolerated

- metal roughness (before tank production): 2μm < Ra < 6 μm

- product roughness is not inspected

Additional surface finishing

Stainless steel sheets with a 2B, 2R or 1D surface finish can be additionally treated based on customer needs and the demands of the technological process the tank will be used for. Additional surface finishes are used to create a different surface pattern and change surface roughness. With the external surface, the emphasis is on its appearance, while the internal surfaces must be smooth and easy to clean.

Škrlj's production capacity encompasses various stainless steel surface treatment processes. Our company has a plain sheet and tank bottom grinding line, a circle polishing machine and an automatic sandblasting chamber (using CrNi beads), and we also offer mechanical polishing and electropolishing services.

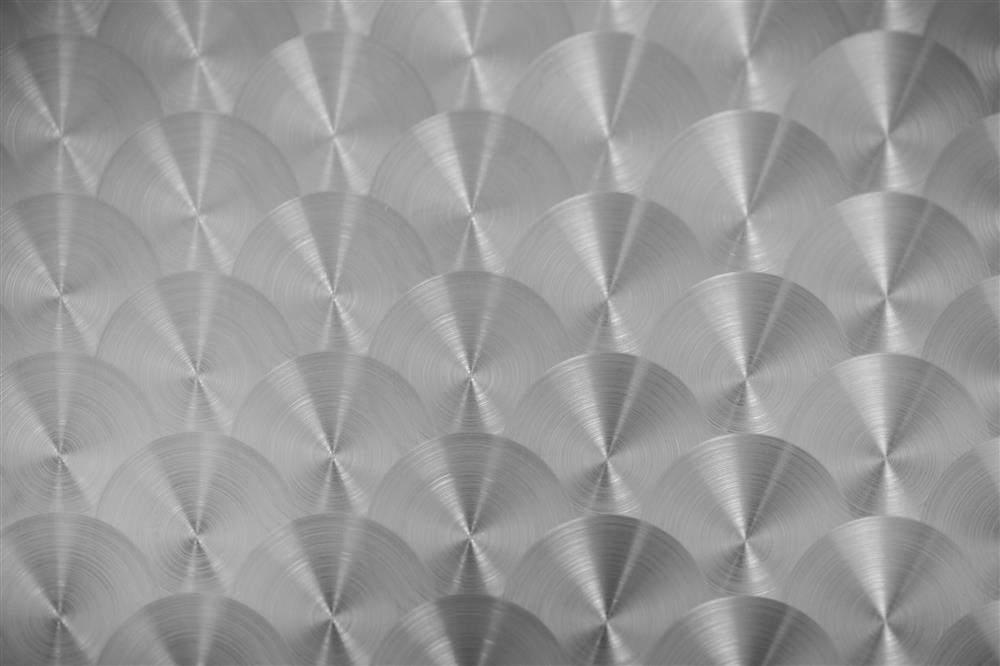

Circle polished - flowered finish

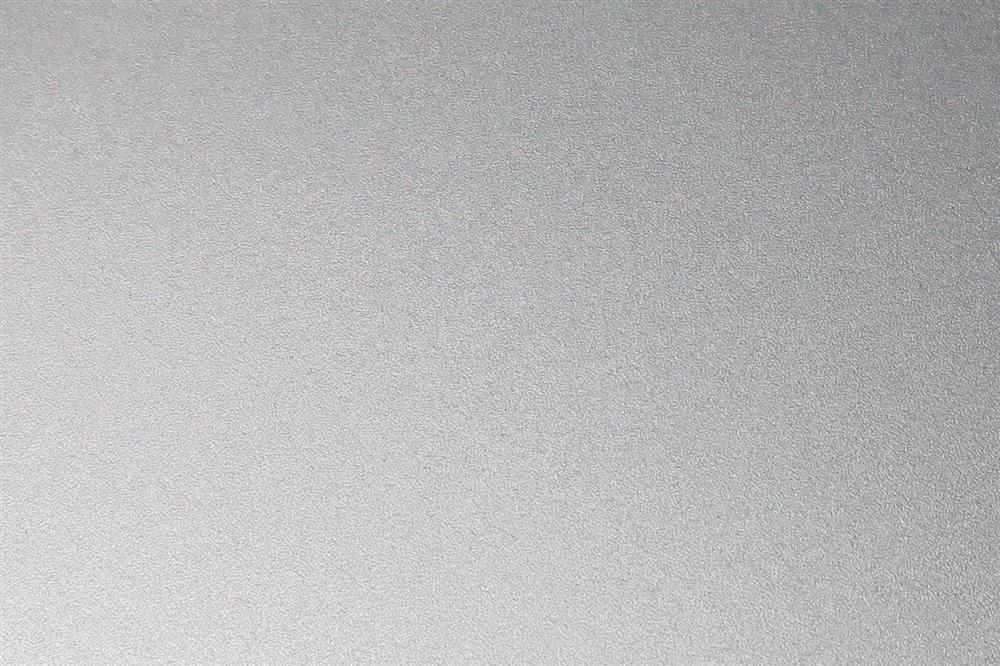

Sandblasted

TiN coating, copper color

Scotch brite

Ground surface K80

Ground surface K120

Mechanically polished surface

Polished surface No.8

Surface properties

| CIRCLE POLISHED - FLOWERED FINISH (K) |

|

|

PASSIVATED |

|

| SCOTCH BRITE (SB) |

|

| SANDBLASTED CrNi beads (S) |

|

| TiN COATING |

|

| GROUND (BC) (BK) |

|

| GROUND B80 / B120 / B180 / B220 / B320 |

|

| MECHANICALLY POLISHED (PC) (PK) |

|

| MECHANICALLY POLISHED P08 / P06 / P04 |

|

| ELECTROPOLISHED E08 /E06 / E04 |

|