Brewery projects

From concept to realization

Do you want to open your own craft brewery? Are you an experienced home brewer who needs extra space and equipment to turn a hobby into a successful business? Read our blog posts "How to start your own brewery" and "How big should your brewhouse be" for more advice on what to bear in mind while you plan such a project.

Modern brewing equipment enables precise brewing control and gives you the ability to lead the process in the desired direction. In order to successfully transform the wort into beer, brewhouses and beer tanks must be equipped with temperature regulation elements. Read our blog post Temperature regulation for more information on our offer of temperature regulation systems.

A project: concept to realization

- analysis of customer demands and requirements

- a project team performs a detailed review of the submitted documentation (plans, drawings, calculations, desired capacity, infrastructure)

- conversation with client, initial project coordination

.jpg)

- review of customer demands for compliance with applicable technical standards

- definition of brewhouse, fermenter, and maturation tank capacity

- material selection, agreement on inside and outside surface finishing, as well as weld finishing, selection of suitable connectors, additional equipment

- preparation of non-binding sales offer

- further cooperation, drawing and offer revision

- after receiving an order it is time to determine the final technical and sales specifications and to prepare the final drawing

- the project is also presented with a 3D model, which enables easier plan and layout review

- preparation of sales order confirmation, expected production end date is determined

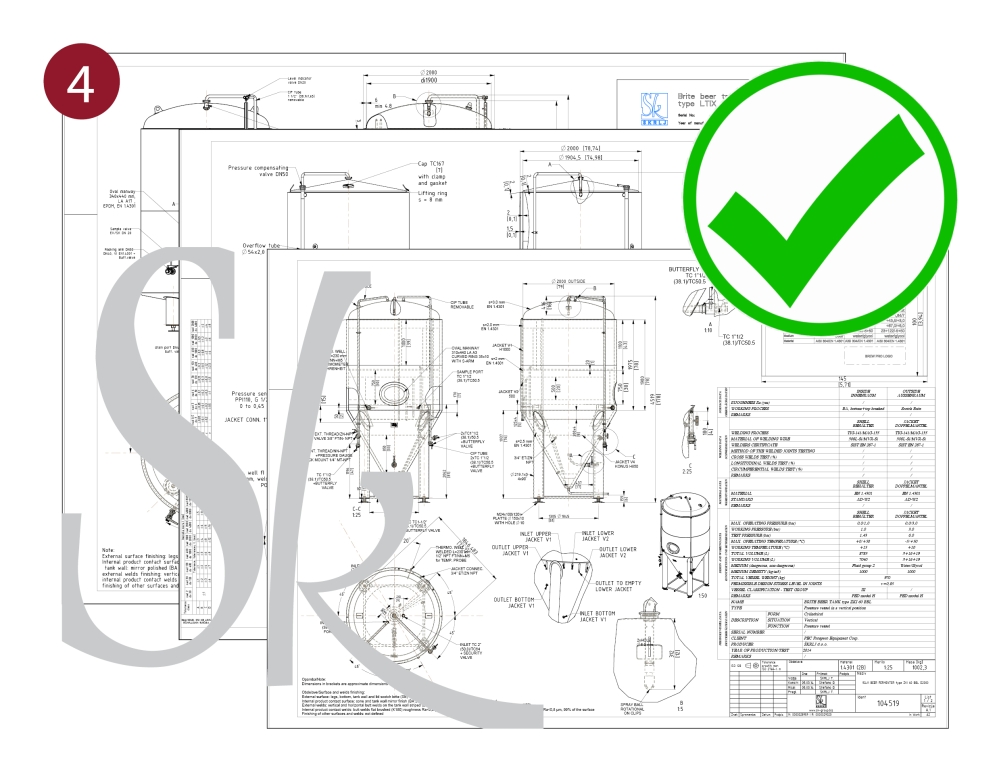

- the customer carefully reviews the technical drawings and the order for any inaccuracies

- our team is always available for further clarification

- once all drawings and sales specifications are confirmed by the customer, the order enters the production preparation stage

- the confirmed order is passed over to our production planning department, where we prepare all the documentation needed for a successful production process

- sales and production processes are run using the SAP program, which enables fast and organized information flow

- production is carried out in accordance with precisely defined work orders, control is carried out throughout the production process

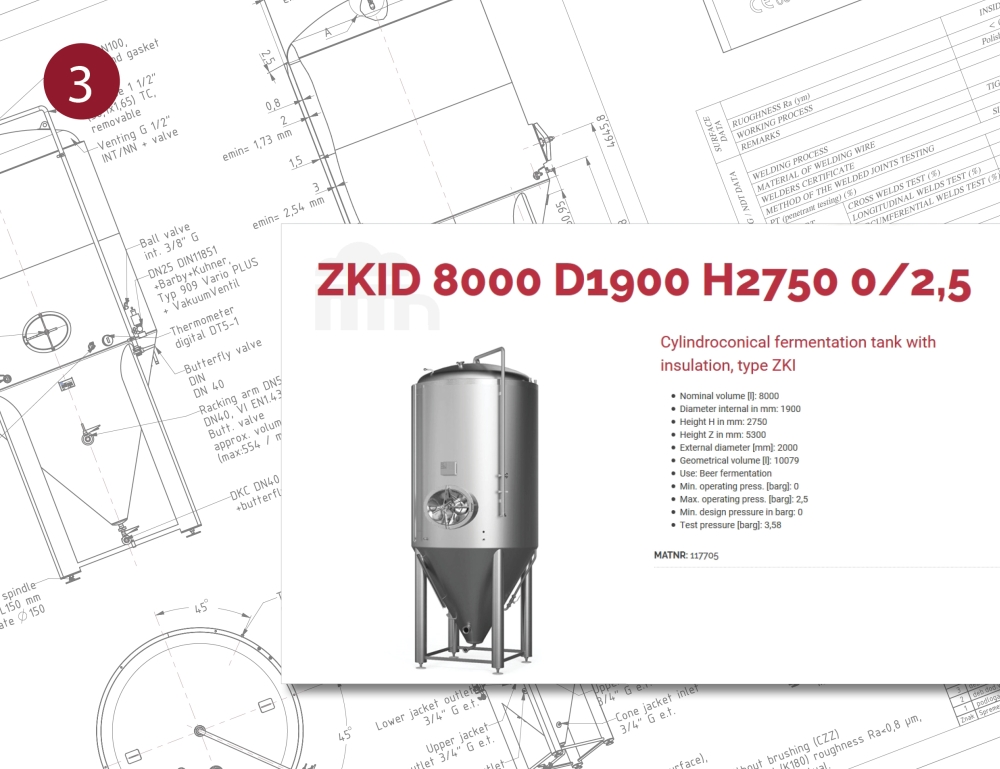

- modern CAD technology (computer-aided design) enables precise project design, technological process and material traceability during production, and organized product documentation

- customers can view the status of their order on the SK Škrlj website

- the finished product is cleaned

- before delivery we perform a final inspection of the product and all its accompanying equipment

- preparation of accompanying documentation (instructions for use and maintenance, instruction manual of built-in equipment, technical drawings, statements, certificates)

- entire product documentation is available to the customer on the SK Škrlj website

- the product is prepared for safe transport

- transport is organized based on the agreement with the customer, we prepare an order delivery schedule

- customers are provided with technical support even after their purchase is completed (phone, e-mail, web conference)

- customers are provided with technical support even after their purchase is completed (phone, e-mail, web conference)

- if problems arise during start-up, they are usually resolved remotely (phone, e-mail, web conference

- quick response in case of maintenance or repair requests

- instruction manual and technical documentation are available to the customer on the SK Škrlj website

BH2 10 HL 6XZKI2000

- Brewery

- Brewhouse BH2 10 HL

- Fermenters: 6 X ZKI 2000 L

- Brite beer tanks: 2 X LTI 2000 L

- Hot water tank: Part of brewhouse

- Cold water tank: 1 X CT1X 1885 L

- Link: TANKPLACE

BH2 10 HL 9XZKI2000

- Brewery

- Brewhouse BH2 10 HL

- Fermenters: 9 X ZKI 2000 L

- Brite beer tanks: 3 X LTI 2000 L

- Hot water tank: Part of brewhouse

- Cold water tank: 1 X CT1X 1885 L

- Link: TANKPLACE

BHM250 3XZMI500

- Brewery

- Brewhouse BHM250

- Fermenters: 3 X ZMI 500 L

- Brite beer tanks: 1 X LMI 500 L

- Hot water tank: 1 X WTX 600 L

- Cold water tank: 1 X CTX 600 L

- Link: TANKPLACE

BHM250 6XZMI500

- Brewery

- Brewhouse BHM250

- Fermenters: 6 X ZMI 500 L

- Brite beer tanks: 2 X LMI 500 L

- Hot water tank: 1 X WTX 600 L

- Cold water tank: 1 X CTX 600 L

- Link: TANKPLACE

BHM500 3XZMI1000

- Brewery

- Brewhouse BHM500

- Fermenters: 3 X ZMI 1000 L

- Brite beer tanks: 1 X LMI 1000 L

- Hot water tank: 1 X WTX 1200 L

- Cold water tank: 1 X CTX 1200 L

- Link: TANKPLACE

BHM500 6XZMI1000

- Brewery

- Brewhouse BHM500

- Fermenters: 6 X ZMI 1000 L

- Brite beer tanks: 2 X LMI 1000 L

- Hot water tank: 1 X WTX 1200 L

- Cold water tank: 1 X CTX 1200 L

- Link: TANKPLACE

- 1

- 2

Green Gold Brewing // Slovenia

Spodnje Grušovlje

Green Gold Brewing is a successful microbrewery from the Savinja Valley, an important hop-growing region in the heart of Slovenia. The brewery is strongly connected to hop growing, as the family's ancestors planted there their first hop plant more than a century ago.

Need some help?

Fill out the form below

We approach every project individually, with every customer's wish and need in mind. A group of experts from various fields work together to find the best solution for our investor. How can we help you? Fill out our form or call us and tell us about your plans. Together, we'll find the right answer.