Food production and storage equipment design, production, and maintenance must be executed in accordance with strict hygiene requirements. Products that are suitable for consumption can only be produced in regularly maintained systems that are clean and disinfected and that contain no harmful microorganisms. That is why CIP equipment has become an indispensable part of modern production process systems.

Save time, money, and energy

Due to the growing level of environmental awareness, an increasing number of manufacturers are opting for more modern approaches to cleaning, which reduce water and energy consumption, use less aggressive cleaning agents and create less waste.

Effectiveness and safety

The advantage of CIP technology is that it enables process equipment cleaning and disinfection without component disassembly. Cleaning and disinfection solutions are prepared in advance and heated inside the CIP station to a suitable temperature. The station is then connected to the tank or device you want to clean. When that is finished, you can activate cleaning solution flow and circulation through the system, but this can only be carried out if the system you want to clean and disinfect is equipped with suitable CIP fittings (inlet and outlet connectors, spray ball in the tank).

The CIP system facilitates the cleaning process, requires minimal physical effort, and the operator does not come into contact with chemical substances during work.

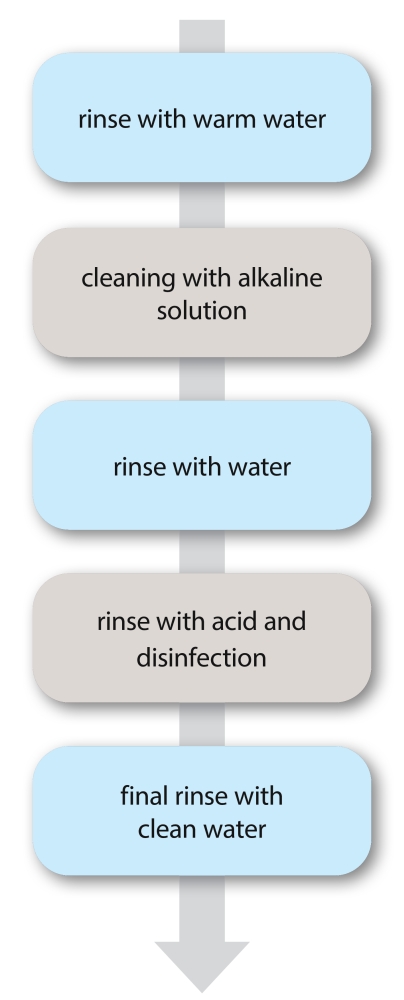

CIP procedure

The effectiveness of the CIP procedure depends mostly on the cleaning time, the cleaning agent, and the temperature of the cleaning solution. Connect all CIP station inlet/outlet connectors to the corresponding inlet/outlet connectors on the tank/device you want to clean. Using the CIP pump, the cleaning solution circulates around the closed system and is then sprayed on the internal tank walls through a built-in spray ball.

The CIP procedure can be used to successfully remove dirt, as well as clean and disinfect the internal surfaces of tanks, pipes, connectors and other equipment, connected to the system.

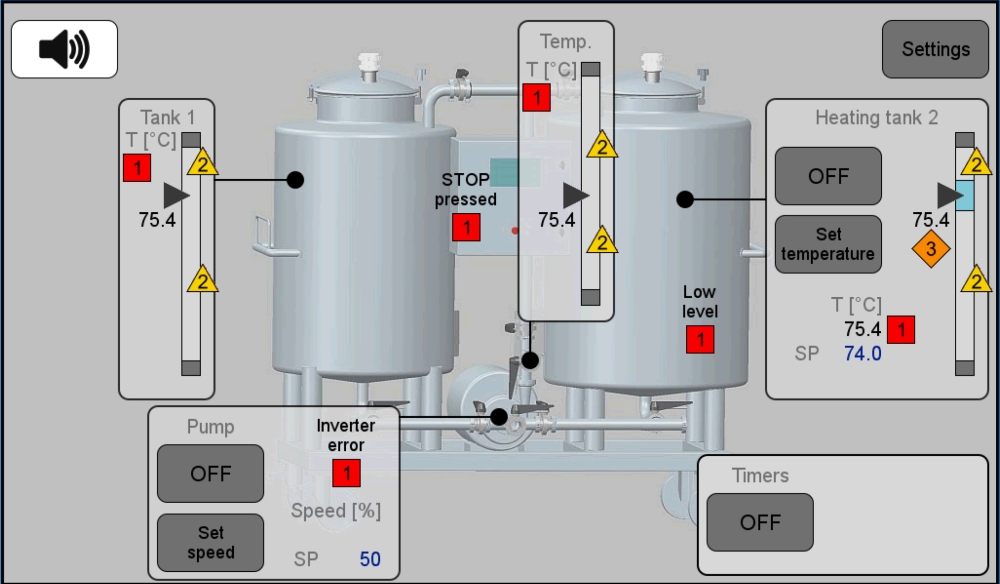

Touch screen control panel

A built-in user interface enables simple operation and process control in each phase.

Main screen:

- device operation (ON/OFF)

- work parameter settings for heating and pump

- current and set value display

- error messages

Timer settings:

- up to 4 individual timers (timer status and alarm activation countdown are displayed on the main screen)

System settings:

- desired (set) temperature

- temperature alarms

- min. and max. pump speed

- language

- display settings

Standards and certificates

SK Škrlj CIP stations are designed and manufactured in accordance with the standards and technical specifications listed below:

- AD2000 Code

- Safety of machinery SIST EN ISO 12100:2011

- Safety of machinery - Electrical equipment of machines SIST EN 60204-1:2006

- Electromagnetic compatibility (EMC)-6-part 1 SIST EN 61000-6-1:2007, SIST EN 61000-6-3:2007

- Quality requirements for fusion welding of metallic materials SIST EN ISO 3834:2006 (1-5)

- Food processing machinery SIST EN 1672-2:2005+A1:2009