Sheet metal cutting

Sheet metal coil cutting

Stainless steel (sheet metal) of various types and thicknesses is delivered in coils, which are mounted onto a decoiler in order to be cut. This is the first step in our production process. The cutting process is carried out according to precisely defined parameters and includes several key stages:

Unrolling, straightening, and cutting

The decoiler unrolls the sheet metal and feeds it through a straightener towards the cutting line. The shears then cut the metal into preset dimensions, tailored to the next stages of the production process and final product requirements.

Application of protective film

When needed, a protective film is applied to the metal to protect the material from damage during subsequent production stages.

Storage

The cut pieces either proceed directly into production or are stored in our vertical sheet metal storage tower where they await the next steps in the production process.

The automated sheet metal cutting process ensures optimal material utilization, minimal handling, and a smooth and efficient production flow.

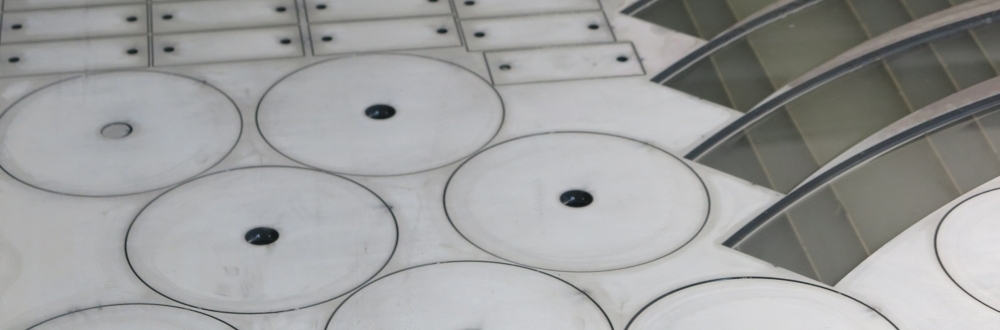

CNC water jet cutting

Abrasive water jet cutting is an environmentally friendly process, as it produces no harmful fumes or waste requiring special disposal. The cutting force comes from a high-pressure jet of water mixed with quartz sand, enabling a cold cut without a heat-affected zone (HAZ). This makes the method ideal for materials sensitive to temperature. It’s especially suitable for thicker materials and for cutting complex shapes.

The high-pressure abrasive water jet (operating pressure range: 0–4000 bar) removes the base material through erosion, delivering precise cuts. The A-Jet cutting head is controllled with a computer software. The adjustable cutting angle (0°–60°) enables various cuts, including circular and curved shapes.

Advantages and cutting capacity:

| Advantages of CNC water jet cutting | - extremely versatile (wide range of materials and thicknesses) - capable of producing complex shapes - cold cutting with no thermal impact, preventing deformation or changes in material properties - extremely precise computer-controlled cutting - high-quality edges, reducing the need for additional treatment - little material loss |

| Suitable materials | stainless steel, aluminum (Al), copper (Cu), structural steel (S235), rubber, plastic, stone, brass, plexiglass... |

| Max. cutting dimension | 2000 x 6000 mm (x,y) |

| Max. material thickness | 200 mm |

| Precision | +/- 0.2 mm |

2D laser cutting with fiber technology

In our production process, we use a state-of-the-art 2D laser cutting machine that enables precise cutting of various shapes (including highly complex designs).

Advantages and cutting capacity:

| Advantages | - extremely low cutting tolerance, ensuring high quality and repeatability - precise cuts and minimal heat-affected zone (HAZ) eliminate the need for additional mechanical edge finishing - CNC control enables fast and automated operation - optimized cutting reduces costs and minimizes waste - different types of sheet metal of various thicknesses, simple design adjustments without tool changes - energy-efficient equipment |

| Suitable materials | all types of steel, aluminum and aluminum alloys, iron, and other materials; square, round, and rectangular pipes |

| Max. cutting dimension | 1500 x 3000 mm |

| Max. material thickness | 25 mm |

| Precision | +/- 0.05 mm |

Robot and COMBO TOWER storage system

Cut sheet metal parts are transferred using an automated system with an integrated robot. The robot picks up the cut pieces and automatically sorts and stores them in the COMBO TOWER storage system, enabling fast, precise, and safe storage. Size limitations of the cut pieces must be taken into account.

| Advantages of the automated storage system | - faster and more precise material flow - safe storage with minimal risk of damage - optimized space utilization - smooth production flow with minimal manual handling - integrated robot and automated storage system enable laser operation even without an operator |

| Min. size (cut parts) | 200 x 200 mm |

| Max. size (cut parts) | 1500 x 3000 mm / 500 kg |

| Capacity (storage tower) | 25 pallets |

| Total load capacity (pallets) | 75 tons |

Storage tower for cut sheet metal

In addition to the robot and COMBO TOWER storage system, we also have a separate storage tower for cut sheet metal.

| Advantages | - pull-out shelves enable fast and easy handling of cut metal sheets - improved accessibility and less additional material handling - real-time inventory overview - max. factory space utilization |

| Capacity (storage tower) | 74 pallets |

| Total load capacity (pallets) | 148 tons |

Laser tube cutting

Laser tube cutting is a high-tech and precise method that enables fast and accurate cutting of tubes with various diameters and wall thicknesses.

| Advantages | - clean, smooth cuts reduce the need for additional mechanical edge finishing - CNC control enables fast and repeatable cutting - minimal heat-affected zone (HAZ), which prevents changes in the mechanical properties of the material - precisely programmed cutting reduces material waste |

| Suitable materials | stainless steel, iron, aluminum |

| Max. tube length | 6,000 mm |

| Max. tube diameter | ∅ 220 mm |

| Max. tube thickness | 10 mm |